Roof trusses are the structural framework used to provide support for a building’s roof. They are prefabricated, triangular in shape and can be made from wood or steel (sometimes both) and are designed by structural engineers.

The triangulated frame of a roof truss is interconnected with members that are strategically in tension or compression and are joined together by special fasteners.

With modern day computer engineering software and factory assembly, trusses are affordable and easy to install.

Trusses truly are an essential building component, and, as an engineering firm, we get asked a lot of questions about them. We decided it was time to answer all of your questions in a complete blog post.

If you want to learn more about roof trusses, please read on.

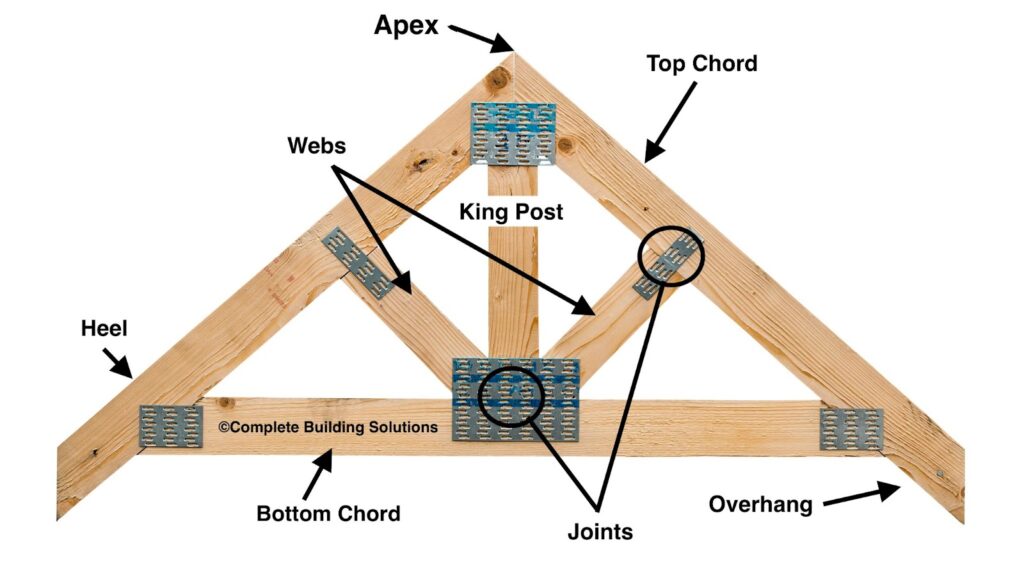

Roof truss components-

You may be interested in learning more about the components that make up a roof truss in order to better understand how they work. You see, the materials used in trusses are nothing more than 2×4’s or 2×6’s, typically. They get their strength from the design. Each piece of lumber or steel is designed with a purpose and is necessary for the long-term durability of the truss system. If one component is damaged, the entire roof truss system is weakened and should be inspected by a structural engineer immediately (we’re serious…it’s a big deal).

Let’s get into it.

Common Roof Truss Components:

Apex- The highest peak in the roof truss is called the apex. Oftentimes, this is the “peak” of the roof.

Bottom Chord: Think of the bottom chord as the foundation of the roof truss. Why? Well, because it’s the horizontal beam that makes up the lowest part of the truss. All the above roof truss components rest upon it.

Girder: A girder is the main roof truss in a roof framing system. All other trusses are framed into the girder.

Heel: The joint in a pitched truss where top and bottom chords meet.

Joint: The point of intersection between a chord and a web or webs, or an attachment of pieces of lumber (eg. splice).

Overhang: The extension of the top chord beyond the heel joint. In English? It’s the distance the top chord “hangs” over its load bearing support system.

Purlin: A purlin is a smaller beam in the truss system that runs perpendicular to the top chords of each roof truss.

Top Chord: The top chord is the beam closest to the top of the roof truss. These are typically slanted and extend over the side of a building.

Web: Webs are beams that connect the top and bottom chords in a triangular fashion. They help to prevent bending within the roof truss system.

Why use roof trusses in roofs?

So, why does modern construction utilize trusses over hand framed rafters?

Easy answer.

Hand framed rafters simply cannot compete with trusses.

Trusses are stronger, easier to install and nicer on the pocketbook. They are delivered to a job site “ready to install” and offer incredible support to a roof while transferring roof and snow loads flawlessly to a building’s main supports.

Here is a breakdown of the main benefits of trusses:

Strong-

Trusses are well designed allowing loads to be distributed appropriately throughout the truss system. This equates to strength and structural integrity throughout the roof supports.

Lightweight-

A truss and all of its components are made from lightweight sections of steel or wood. This setup is typically easy to transport and install.

Versatile-

There are thousands of truss design options available today. If you have a structure, there is truss out there to fit it.

Affordable-

Trusses cut labor costs significantly. There is no denying (in most situations) that trusses are more affordable than hand framed rafters because of this.

Allow for open-concept plans-

Since trusses can span long distances without needing any posts or interior supports, they are perfect for open-concept designs which are incredibly popular right now.

More environmentally friendly-

Trusses utilize less timber and produce less waste than other methods. Unused timber/steel during production can be recycled or used for other projects.

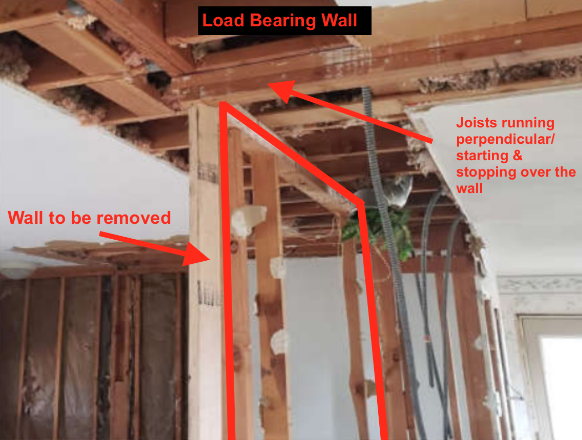

Do roof trusses need load bearing walls?

So, this is the beautiful thing about roof trusses….they don’t need interior load bearing walls for support. In fact, they are designed to remove the need for this altogether.

Traditional hand framing required the use of load bearing walls in order to properly transfer roof and snow loads to the footings.

Side note- If you’re remodeling and your home has rafters, you better get a structural engineer on site before you even consider removing walls in your home. It’s always important to seek a professional before pulling walls, but especially if rafters are involved. Removing a load bearing wall without the proper plan in place can have devastating results such as home collapse or other long term structural damage.

Moving on.

The development of the roof truss system was a huge advancement in construction methods for this reason alone.

They can literally span 40, 50 or even 90 feet without any interior support. This is because the trusses themselves are engineered to bear the load of the roof and snow loads and transfer this weight to the exterior walls.

Longer roof trusses may require some additional “beefing up” of the truss system in order to maintain stability over the long span. This could mean steeper slopes or more internal webbing.

The material used also plays a role in roof truss span length. Commercial buildings often need to span extremely long distances and therefore will utilize steel instead of timber. Ultimately, steel is capable of bearing larger loads and has greater longevity than timber.

Warning- Just because your house has trusses, don’t assume you can start taking down walls without consequence. It’s crucial to the structural integrity of your home or building to identify load bearing walls prior to removal. Call a structural engineer to help you determine which walls are load bearing in your home. In the meantime, here’s a great blog we put together at identifying load bearing walls.

Get a free quote on your project!

Ready to start your project? Reach out to Complete Building solutions and get a quote absolutely free.

Common roof truss design errors-

Because of modern engineering software, it would be extraordinarily rare to have a design error in a roof truss system.

This does not mean that issues don’t exist.

If there was a problem with a truss it probably occurred during transportation or installation.

Any damage to a truss member can lead to structural integrity issues within a home. This is because each component of the roof truss is essential to a home’s load path. The load path in its entirety is disturbed when a roof truss member is compromised.

What does this mean?

Well, the structural system could become unbalanced meaning too many loads are sitting on certain areas causing stress. You may hear a loud bang, or notice cracking, severe settling or other structural issues within the home.

A few things to look for:

- Broken or cracked web members

- Broken or cracked top or bottom chords

- Fasteners (ie gusset plates) that are dislodged or out of place

Reasons for roof truss failures-

As we mentioned above, design issues are rarely the reason for roof truss failure. Ok, so what is? Check the list below.

Possible roof truss failure causes:

- Lack of or improper permanent or temporary bracing

- High winds during installation

- Transportation damage

- Post installation alterations to a roof truss without structural engineer approval

- Gusset plate failure

- Improperly repaired truss

- Extremely heavy snowfall

- Overloading (for example, consider a butcher shop…hanging weight of animals may call for “beefed up” trusses)

- Heat loss in the attic

- Cutting webs or chords to accommodate mechanical equipment (or for any reason) requires a repair

- Holes may compromise the strength of the lumber, even if each individual hole is small.

Warning- Roof truss systems should NEVER be altered without a structural engineer’s approval & scope. As an engineering firm, we’ve seen a few DIY roof truss alterations that did NOT go well. It’s best to get an opinion before messing with your home’s structural system.

In general, roof truss systems can start to wear down overtime. It often has to do with water damage or heat loss in the attic. We will discuss this further in the next section.

Can roof trusses get wet-

No. Roof trusses should NOT get wet. Condensation and roof leaks are often the cause of roof truss failure.

How does this work? Well, water is the #1 enemy of your home. If there is a leak in your roof and that water sits on the building components, they start to break down and lose integrity. Repeated exposure only worsens the condition.

Need proof? See the photo below (hand framed rafters destroyed by water damage).

What about condensation? Well, condensation is often a problem when there is heat loss in the attic.

What is heat loss? It’s when warm air from the conditioned living space moves into the attic. The attic is supposed to be a cold space that nearly matches the exterior temperature. But, when the attic has open bypass or poor insulation, warm air may move up from the home into the attic. The warm air meets the cold air and causes condensation. Again, moisture is detrimental to building components.

An even bigger problem could be the heat loss itself. You see, the bottom chord of the truss is usually covered in insulation which means it will stay dry, causing it to shrink. In attics with high humidity, the top chords (located higher than the insulation) may absorb that moisture causing the chord to swell. This uneven shrinking and swelling can cause extreme issues such as truss failure or uplift.

Yikes!

Ever hear loud “BOOMS” coming from your attic? Well, this mechanism may very well have a part to play in it.

The solution? The heat loss issue needs to be addressed. And, we don’t mean simply adding more insulation to your attic. The insulation will be rendered useless if you do not first air seal open bypasses.

Attic bypasses are any unsealed area between the conditioned living space and the unconditioned attic space. It could be things like: chimneys, ceiling light fixtures, heating ducts, kitchen and bath exhaust fans, plumbing, electrical wires, dropped ceilings and soffits.

If you have more questions on stopping heat loss in your attic, reach out to Complete Building Solutions or check out this blog here.

Can roof trusses be repaired?

You can absolutely have a truss repaired. But, the repair must be designed by a licensed professional structural engineer.

The engineer will need to analyze the extent of damage done to the truss but also to any other parts of the home (ie did structural movement occur?). They then will need to create a plan to remediate the issues.

Once a plan has been formed, your contractor can start work.

But, don’t take it from us. Here is what the code says.

IBC 2303.4.5 / IRC R502.11.3 & R802.10.4 • Alterations to trusses.

“Truss members and components shall not be cut, notched, drilled, spliced or otherwise altered in any way without written concurrence and approval of a registered design professional. Alterations resulting in the addition of loads to any member (e.g., HVAC equipment, piping, additional roofing or insulation, etc.) shall not be permitted without verification that the truss is capable of supporting such additional loading.”

So…call your structural engineer if a repair needs to be made or if you know that an unauthorized alteration has been made to your roof truss.

Earlier in this post we included some photos of a client’s attic. They had some damaged trusses and we were called out to engineer the fix. See below.

There can be a TON of work that goes into something like this. That is because each member on a truss was designed in a specific way in order for the truss to function as a whole. The engineer must go through and perform calculations on each member of the truss to make sure the system can transfer loads appropriately. They also consider axial forces such as tension and compression as well as shear and moment forces. Each member of the truss system will be affected by these forces.

Can roof trusses be modified?

First, let’s define what a truss modification is and how it is different from truss repair. Truss modification can be defined as, “altering a truss profile, loading, and/or bearing conditions to fit a situation for which the original truss was not designed.”

This is different from truss repair which can be defined as, “restoring a truss back to its original shape and strength in situations where damage has caused a change or a reduction in either.

So, truss modification involves altering a truss in order for it to perform in a way it was not intended to while truss repair is restoring the truss to its original shape.

Let’s answer the question. Can trusses be modified? Yes, they can be (usually). Here comes the BUT…..you need to have a structural engineer design the modification for you since it is a structural change. Remember, every single component on an engineered truss was designed to contribute to an overall goal. Altering just one member on this system can throw the whole system out of balance (if not done correctly by an engineer) possibly leading to structural damage in a home.

Some of you may be wondering when or why you would want to modify a roof truss. There are plenty of reasons.

The most common may be:

- Putting a bonus room over the garage

- Renovating the attic to utilize “wasted” space for storage

- Turning an attic into a living space

- In order to make room for HVAC equipment

- Moving a stairway

- Raising a ceiling in a specific area of a home

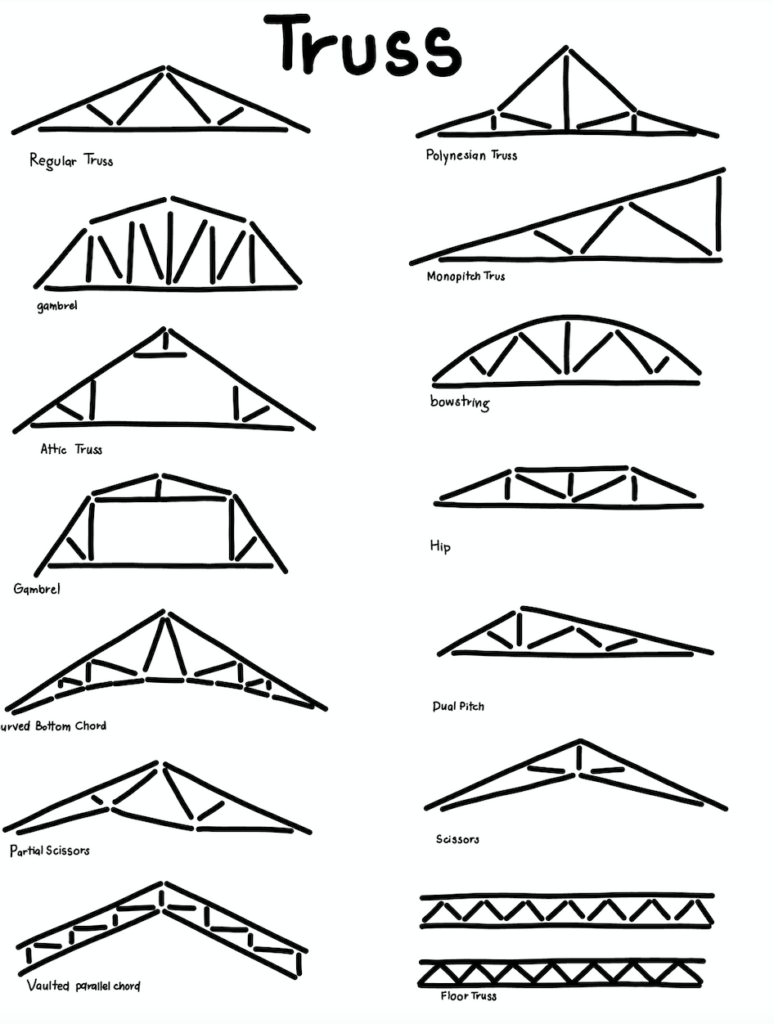

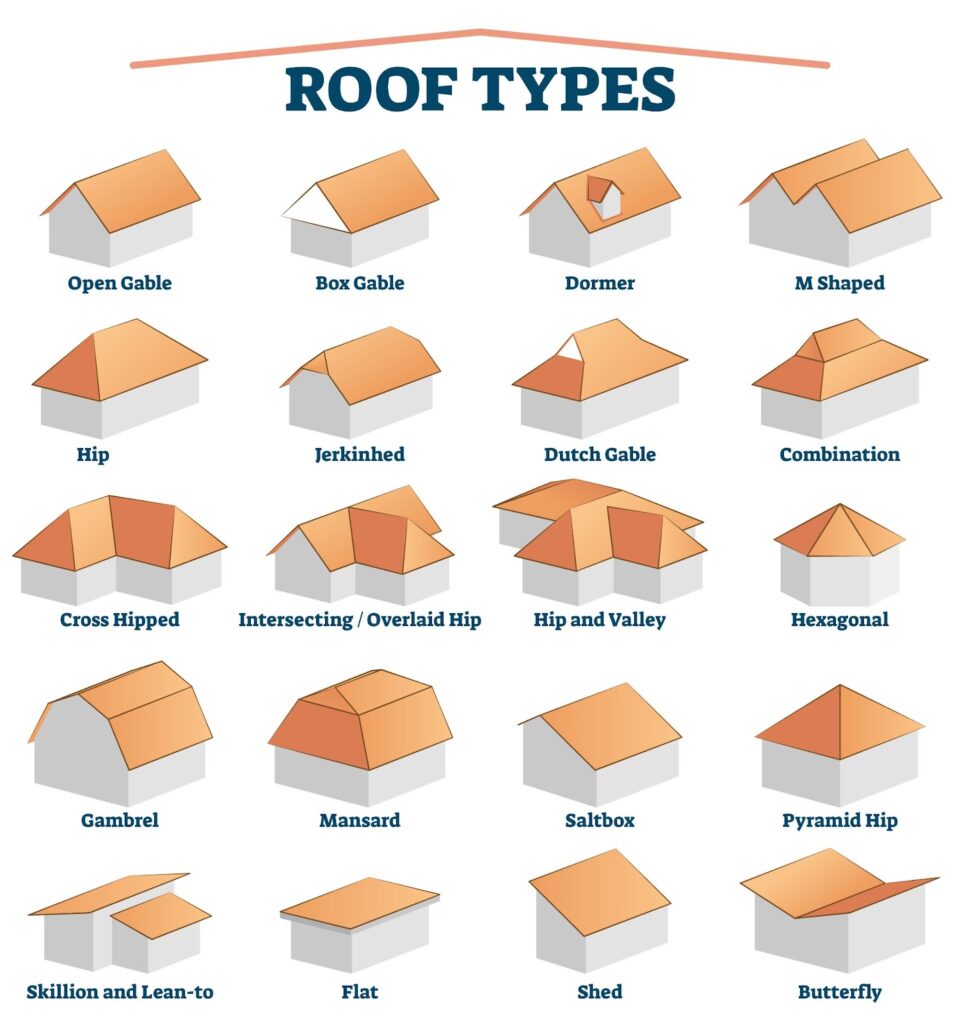

Roof Truss Types-

There are literally thousands of different types of roof trusses.

Here are some common roof truss types:

- King post truss– These are the most simple (and cheapest) of all truss types. They utilize the least amount of truss members: two top chords, one bottom chord, a king post (central upright post) and two webbing chords. Because of this, they cannot span great distances and therefore are typically used for smaller projects ie) additions, garages or other short-span projects.

- Queen post truss– Queen post trusses are simple and sturdy like the king post truss. However, instead of one upright post in the center, they have two queen posts connected by a beam. These posts make them able to span greater distances than king post trusses, making them eligible for larger residential projects.

- Fink truss– Categorized by the “W” webbing shape, Fink trusses are one of the most common trusses out there for residential construction. They can span great distances and are very cost-effective.

- Attic truss– Attic trusses are utilized when a living space is required within a roof zone. Larger timbers sections are often incorporated to support additional live loads.

- Scissor truss– These are most commonly used in residential construction for vaulted ceilings. The appearance of the truss resembles a scissors, hence the name. These trusses can get a bit pricey.

- Gable truss– Gable trusses are utilized in residential gable roof construction.These trusses are usually used in combination with other truss types and serve as the “end cap’ for the roof. Therefore, they can be found on the ends of the roof framework.

- Mono truss- Mono trusses slope in one direction They are often used in porches in order to form roofs with hip ends.

- Raised tie truss- These are installed when the internal ceiling height is required to be higher than that of the wall plate.

- Hip roof truss- Can you guess what these are for? You got it, hipped roofs. Hip roofs slope on all sides. This means that hip roof trusses need to be custom engineered to make sure the slope and ridges are correct.

- Flat roof truss- These are typically used in commercial buildings or new construction homes with flat roofs.

How to know what type of roof truss I have?

There are three main factors to consider when determining what type of roof truss you may need.

- Roof shape- Usually, in the United States, homeowners have 1 of 3 roof shapes: gambrel, hip or gable. This alone will give you a starting point on what type of truss you may have. Ie) Hip roofs utilize hip roof trusses.

- Ceiling type- The ceiling type of your home can help you determine what roof truss may have been used. For instance, vaulted ceilings often utilize scissor trusses.

- Attic space- If you have an attic with a living space, you probably have attic trusses.

If you have other questions about your roof trusses, hire a structural engineer to perform an inspection and answer your questions.

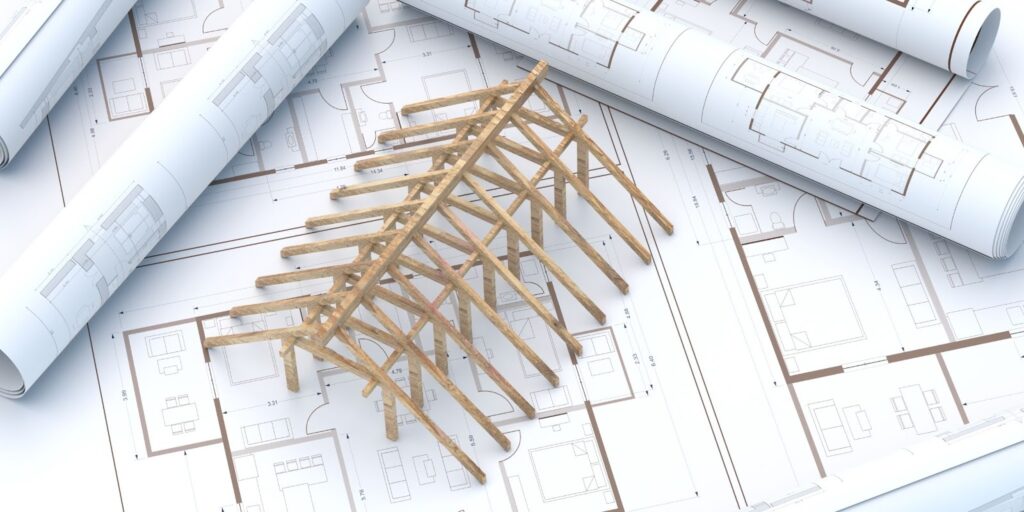

What is roof truss design?

Roof trusses need to be designed by an engineer. There are a few ways this can be done.

- Software- Trusses come manufactured and ready to install when purchased via the manufacturer. Truss companies utilize engineering software in order to get their designs right. It makes the most sense to order trusses for a new construction build in this manner because it’s quick, affordable and easy.

- By hand- There may be circumstances when an engineer needs to design a truss by hand. This entails fervent calculations/analysis and is very time consuming. Typically, it is in response to a truss repair or modification. If you have discovered a broken truss or know your trusses need modification due to a remodeling project, please be sure to reach out to a structural engineering firm for help.

What size roof trusses do I need?

Your structural engineer and contractor will be able to help you with this. However, here are some of the major factors involved with calculating roof truss size.

- Span- Measure the distance between the home’s exterior walls

- Rise- Measure the height of the roof at its most central point

- Pitch- The roof’s pitch will matter. It’s important to know this.

- Overhang- Knowing the measurement of the eave is important for calculating the correct truss size.

What about how many you need?

If you want a quick and easy “ballpark” on how many trusses you’ll need, you can use the following equation (remember this is just a guess, an engineer should be involved).

Rough estimate of how many trusses you will need: (Roof length/2=# of trusses)

For example) if your roof is 40 feet long, you will need approximately 20 trusses.

Note- Always check local building codes as well. Truss spacing can vary depending upon location due to heavy snow loads or high winds.

Where to buy roof trusses?

You can buy roof trusses through home improvement retailers like Lowes and Home Depot. You can also buy them directly through truss manufacturing companies. Just search for “truss manufacturing company near me” in your internet browser. You will get a whole list of companies. Contractors will typically have relationships with such companies and therefore can do the ordering for you.

How long does it take to install roof trusses?

With a 3-4 person crew it typically takes a few hours to a day. This will vary based upon roof size, site conditions and equipment used. Installing trusses with a crane will make the entire process easier and quicker.

Side note- Weather will greatly factor into how quickly the job can be done. If it’s windy or rainy, a crane may not be able to safely operate. Or, if it’s extremely muddy, heavy machinery may struggle to move around or dig up the building site. Your contractor will do their best to give you a timeframe.

When did roof trusses become popular?

The first trusses were designed in the 1950’s. However, it wasn’t until the 1960’s-1970’s that trusses really started to become popular. Hand framing was basically over by the 1980’s.

Are roof trusses cheaper than rafters?

Without a doubt, roof trusses are cheaper than rafters. The savings is in the labor.

Roof trusses are delivered to a job site ready to be installed and they go in quickly.

Rafters, on the other hand, require highly skilled carpenters (which can be tough to find) and TIME.

What do roof trusses cost?

The standard roof truss cost for a 2,000 square foot home may be anywhere from $7,500-$12,000.

But, of course there is no actual “standard” when it comes to roof trusses, so you can’t really go by this number. Costs will vary based upon a few factors.

Factors affecting cost of roof truss-

- Truss size- The size of the truss will increase costs. For example, a 30-foot-span truss may cost around $3.25-$4.25 per foot. On the other hand, a 26-foot-span truss may be closer to $3.00-$4.00 per foot. Also, know that the larger and steeper your roof is, the more expensive the truss may be.

- Truss type-The type of truss you order will also affect costs. We talked about this earlier in the truss type section. For example, Fink trusses are among the most affordable ($120-$260 per truss without installation) while Scissor trusses can cost much more ($120-$500 without installation).

- Material-Trusses are typically made of wood, steel or a combination of both. Wood is more affordable but vulnerable to the elements. It is commonly used in residential construction. For materials alone they cost about $60-$500 per truss. Steel is more expensive but holds up better and spans larger distances. Just for materials, steel trusses cost about $150-$700+. Steel trusses are typically used in commercial and agricultural projects.

- Labor: The labor costs to install roof trusses is about $20-$75 per hour on average. However, the total labor costs will vary based upon the size of the roof, truss type, location and job complexity. Note- Labor costs are usually higher in urban areas where the costs of living are greater. Remember that there will be disposal fees tacked on to your final bill as well.

Costs for common truss types-

Truss type was one of the factors we mentioned above. We figured it would be helpful to go into a bit more detail on this here.

Scissor truss/vaulted ceiling cost-

These trusses are used for open concept vaulted ceilings, attics and A-frame style homes. Scissor trusses can cost on average $120-$500 per truss for materials.

King post truss cost-

King post trusses are the most simple truss you can utilize. This is because of their basic design and minimal materials needed. They cost about $60-$160 per truss without labor.

Attic roof truss cost-

These trusses are used to create a livable attic space and therefore are designed to carry more weight than other forms of trusses. Each attic roof truss can cost $100-$400 for materials.

Gable/end truss cost-

Many residential houses utilize gable trusses at each end of the home. They do cost a bit more than other roof trusses. This is because they offer greater structural support to the home and therefore use more lumber in their design. Material costs for gable roof trusses can be approximately $80-$800 per truss.

Well, there you have it.

It’s our goal that you learned a few things about roof trusses, their design and what they do in this blog post. We’d love to hear from you so please post any comments or questions you may have down below. As always, if you have additional questions you can call us at 763-544-3355.