Steel beams are an essential building component used in framing to carry heavy loads in residential, commercial and bridge construction projects.

These beams are strong and capable of spanning exceptionally long distances which is why they are so often utilized for many types of construction.

They also do not rot, are durable, recyclable and more fire resistant than timber beams.

Interesting fact, each steel beam used in a building project has been perfectly analyzed by a structural engineer to ensure it can properly support the structure at hand.

It’s a very involved process.

If you are looking to learn more about this phenomenal construction asset, please read on.

Here’s what will be covered:

What are steel beams-

What are steel beams used for-

When is a steel beam required-

Steel beam: advantages & disadvantages-

What are steel beams made of-

What is a steel I beam-

Steel beam types-

-Cross section

-Support type

-Geometry

What steel beam size do I need-

How to design a steel beam or calculate load capacity-

Can steel beams be welded or bolted together?

Are steel beams expensive-

How to read steel beam sizes-

What grade steel beam is used in residential homes-

Let’s begin.

What are steel beams?

Steel beams are an essential structural component in the framing of buildings and bridges. They are made from structural steel, an alloy of carbon and iron and come in various shapes and sizes.

Why are they so important?

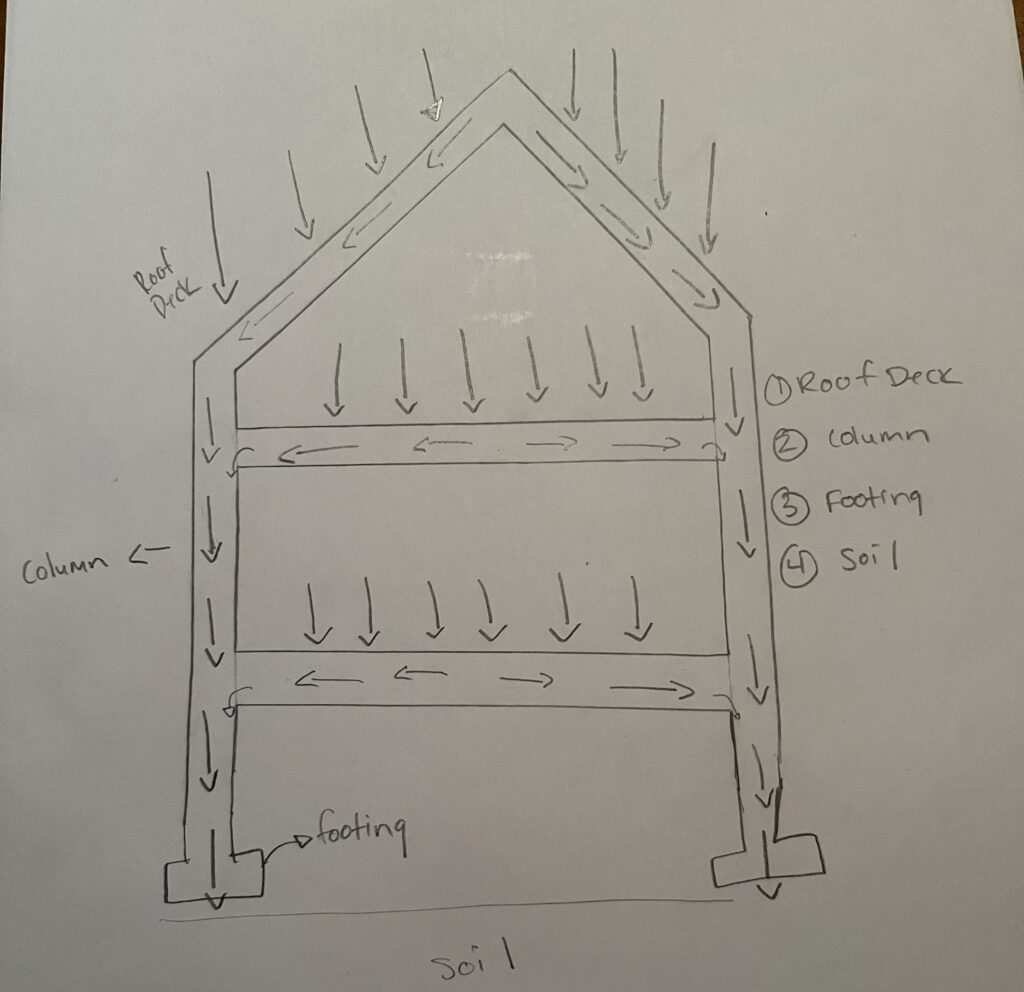

Their role in transferring loads from the rooftop down to the soils is paramount. This “path” the loads travel down is termed the load path of a structure. Structural engineers are able to create strong buildings because of a well designed load path.

Just to clarify, load path is the direction in which each consecutive load will pass through connected members. For example, the snow load on the roof must be properly transferred to the structural components in the attic. The snow loads and the attic loads must then be properly transferred to the structural components of the floor below it and so on.

Here’s a very basic picture demonstrating this.

In structural framework, steel beams will span horizontally between columns, supporting the loads above them. The type of steel beam selected for a project will completely depend upon the loads it must carry. Structural engineers have extensive knowledge when it comes to selecting the right steel beams for a job. Fancy math and various calculations are utilized to determine the proper size the steel beam should be for the building to stay upright overtime.

What are steel beams used for?

We touched on this a bit above. Steel beams are a part of the skeleton that makes structures strong. They are used in construction to support structures like residential, industrial and commercial buildings, skyscrapers, stadiums, bridges, and cargo ships.

Essentially, the steel beams carry the vertical loads above them. In some cases they may even be used to support horizontal loads from things like earthquakes.

Can you imagine a home or a bridge without a beam? Floors could not exist and buildings would fall apart.

When is a steel beam required?

Steel beams are a main building component used in framing of all kinds.

You may be wondering if a steel beam will be required in your project?

Well, the best way to know is to consult a structural engineer.

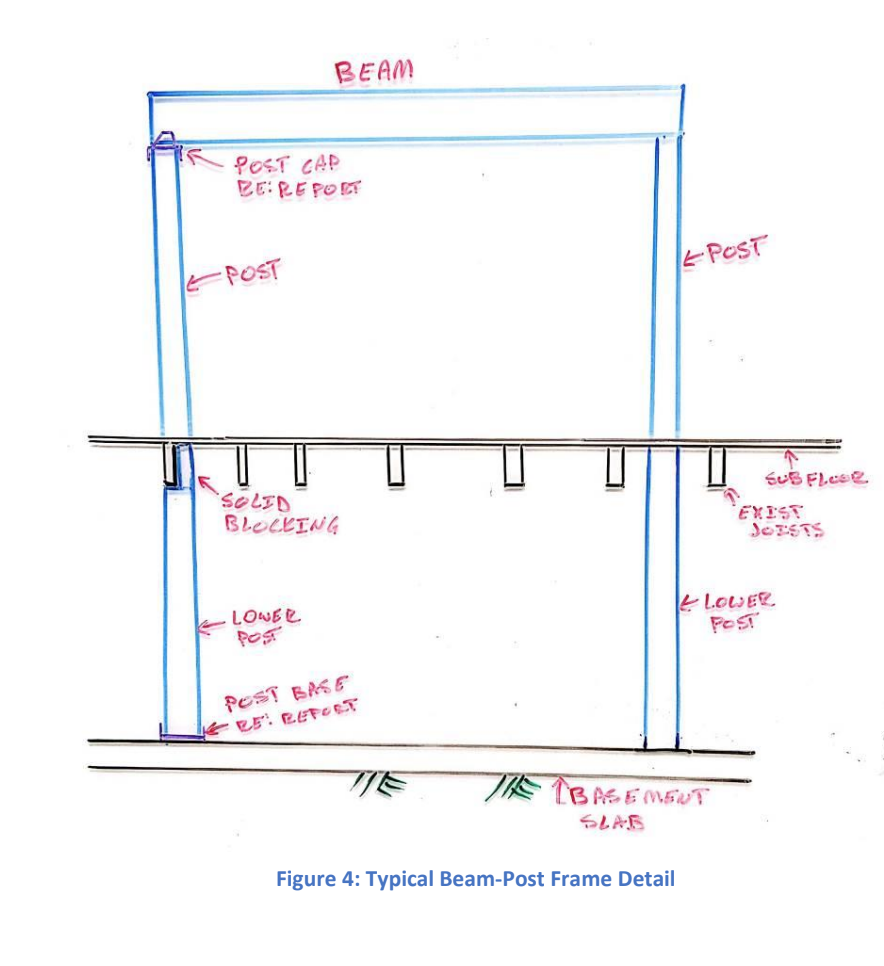

Usually, in residential construction, a steel beam or timber beam will be used as the main support beam in the basement. Steel beams are a common choice because they are extremely strong and can span very long distances. They’ve become much more popular in residential construction over the years.

Here’s some fun background for you.

Before the 1940’s, timber beams were primarily used. It wasn’t until the 1940s-1960s that steel I beams became popular choices for the main basement beams in residential homes.

Why?

Well, either people got taller or people were sick of hitting their heads on basement framing.

You see, steel beams can carry heavy loads and provide a lot more head room in the basement than a timber beam can. For example, a 6 inch I beam can carry just as much weight as a 14 inch LVL and provide a lot more headroom due to its smaller size.

So, it’s extremely common to see steel beams used in timber framed homes.

You may be wondering why homes tend to be timber framed over steel framed. It’s actually really interesting. You’ve probably noticed how steel buildings tend to be hot in the summer and cold in the winter, right? This is because steel is a great conductor of heat.

In northern climates, this could become a problem and pose possible building envelope issues. When cold air travels through metal into the building envelope (for instance the metal touches the exterior plywood or inside sheet rock) and meets a warmer climate, condensation can occur. This can lead to water and mold issues over time.

Yikes, no one wants to deal with that.

Let’s move on to the good, bad and the ugly in our next section.

Steel Beam: Advantages & Disadvantages-

This section is all about the good and the bad. Let’s jump in.

Advantages of steel beams:

- Durable- Steel can tolerate much larger loads than wood or stone due to its high strength-to-weight ratio.

- Recyclable- The great thing about steel is that it can be melted down and re-purposed. It’s a great way to avoid construction waste.

- Rust-resistant & anti-corrosive-The chemical make-up of steel allows it to resist rust & corrosion. They also do not rot the way wood does.

Disadvantage of steel beams:

- Challenging to move and alter- Steel beams often require a crane to be lifted into place. They are extremely large and can pose challenges in this sense. Unlike wood, steel can be harder to alter on site. If changes to a plan arise, new steel may need to be ordered if it cannot be altered at the job site.

- Maintenance- Steel does require some maintenance. Although they are anti-corrosive, measures still need to be taken to keep the metal functioning at its best. Your steel may require a protective coating or paint.

Since we are a structural engineering firm and do work with a lot of residential customers, we thought we’d include advantages and disadvantages of steel beams specific to residential construction.

Here we go.

Advantages of using steel beams in residential construction-

- Durable- We will use this one again. Steel beams are extremely strong and they do not splinter or warp the way timber beams can. These beams can withstand the test of time.

- Cost effective- Steel beams are actually cheaper than many other materials. Your structural engineer will size every beam on your plan. Then, your contractor can order the designated beams. Once the beams are delivered on site, they just need to be installed. No on-site rework necessary which definitely saves on labor costs.

- Steel beams are light- Are you surprised that steel beams can actually weigh less than concrete or timber beams? This saves on transportation fees.

- Custom sizes- Did you know there is no one standard sized steel beam? Structural engineers will look at your plan and tell you the size beams you need. Luckily, steel can be molded into any size or shape.

- Tensile strength- Steel beams have a high strength per unit mass. This means it is capable of carrying higher stresses without bending or breaking.

Disadvantages of steel beams in residential construction-

- Maintenance- Steel beams are rust resistant not rust proof. Condensation can cause a beam to rust.

- Environmental pollution- Steel beams are extremely popular in the construction industry for all the above mentioned points. However, the process of making steel beams can hurt the environment. Plus, iron production uses massive amounts of water which of course has its own risks.

Get a free quote on your project!

Ready to start your project? Reach out to Complete Building solutions and get a quote absolutely free.

What are steel beams made of?

Steel beams are made out of structural steel.

What is structural steel you may ask? We do have an entire blog post on this topic alone. Just click here.

In general, structural steel is simply steel (an alloy made out of iron and carbon) containing a carbon content of 0.05-0.25%.

You see, steel is made by first extracting iron from iron ore. Then, carbon is added to strengthen the overall substance. At this point the mixture is considered steel. But, the carbon content in the mixture is too high to be considered structural steel. So, it must be reduced until the carbon content reaches 0.05-0.25%. This percentage of carbon is the sweet spot providing structural steel with extreme strength.

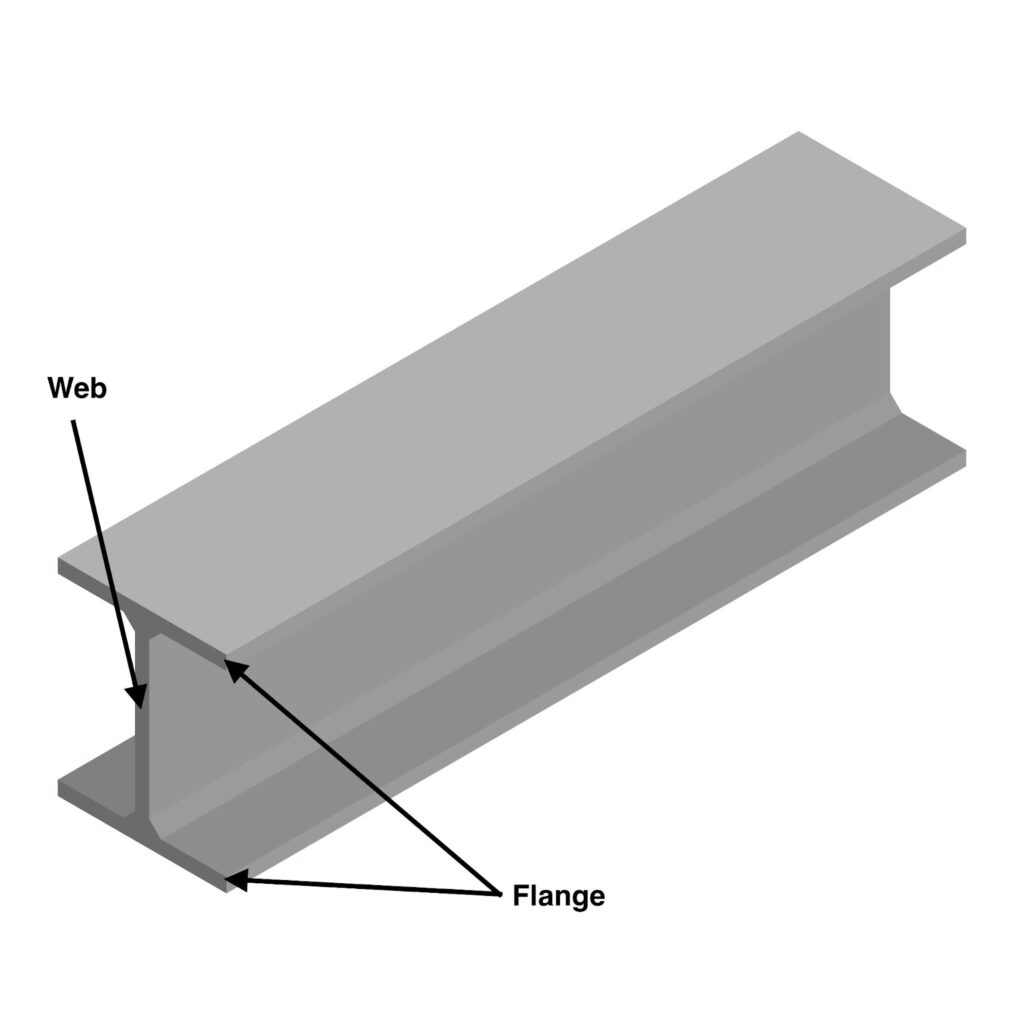

So, we’ve talked about the material steel beams are made out of. What about the parts that comprise a steel beam?

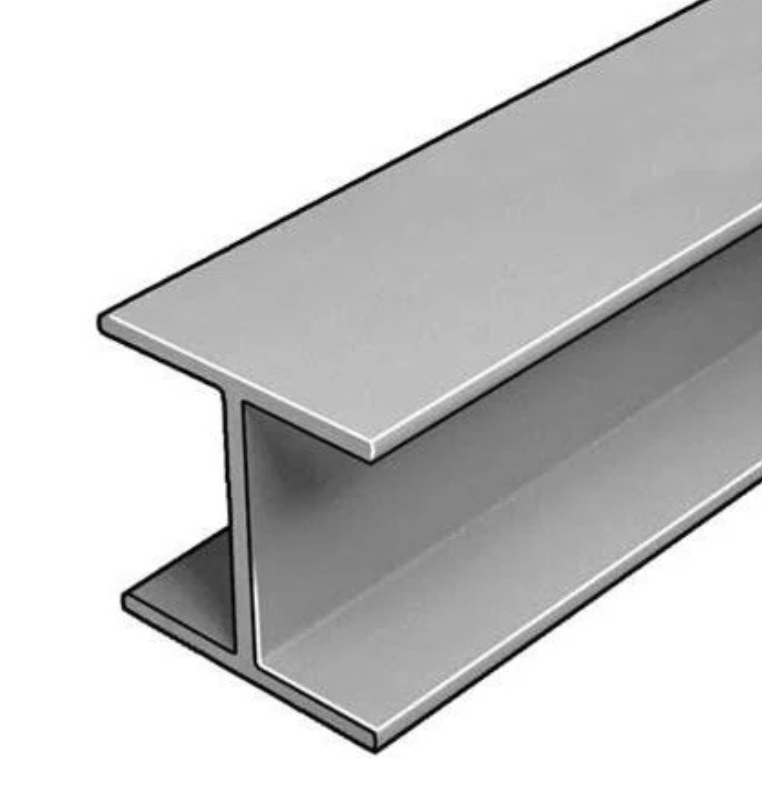

This will depend on the type of steel beam (we will get into this in the next section). However, the most common steel beams are wide flange beams which have two horizontal planes, flanges, joined together by a vertical beam, a web.

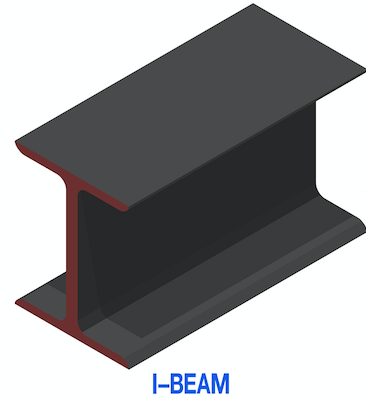

What is a steel I beam?

We will talk about I beams in the steel beam types section below. However, this is such a highly requested topic that we felt it deserved its own section.

So, what is a steel I beam?

Well, I beams are actually considered the universal beam because they are capable of supporting a wide variety of loads. They are extremely common and found in most building structures.

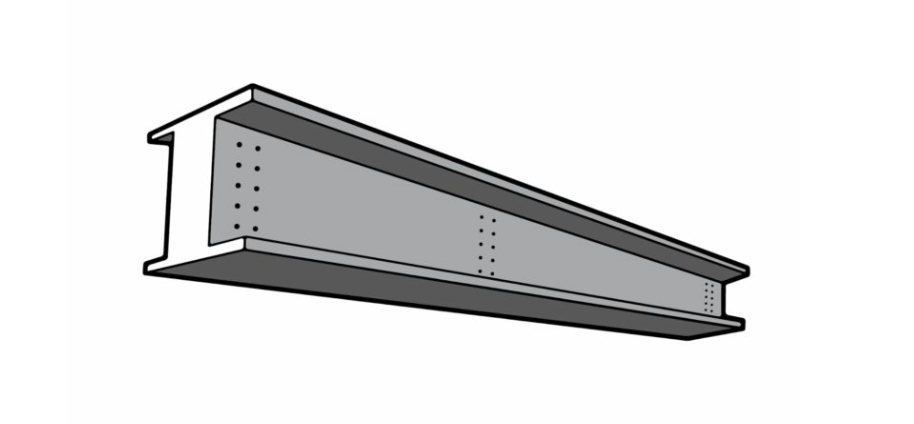

As the name implies, they are shaped like the capital letter I and are made of two horizontal planes (flanges) connected by one vertical member (web). They can be found behind the walls of hospitals, skyscrapers, parking garages, bridges, warehouses and other large buildings.

The size of the I beam completely depends on what the structural engineer dictates, which is based upon the loads the beam is designated to carry.

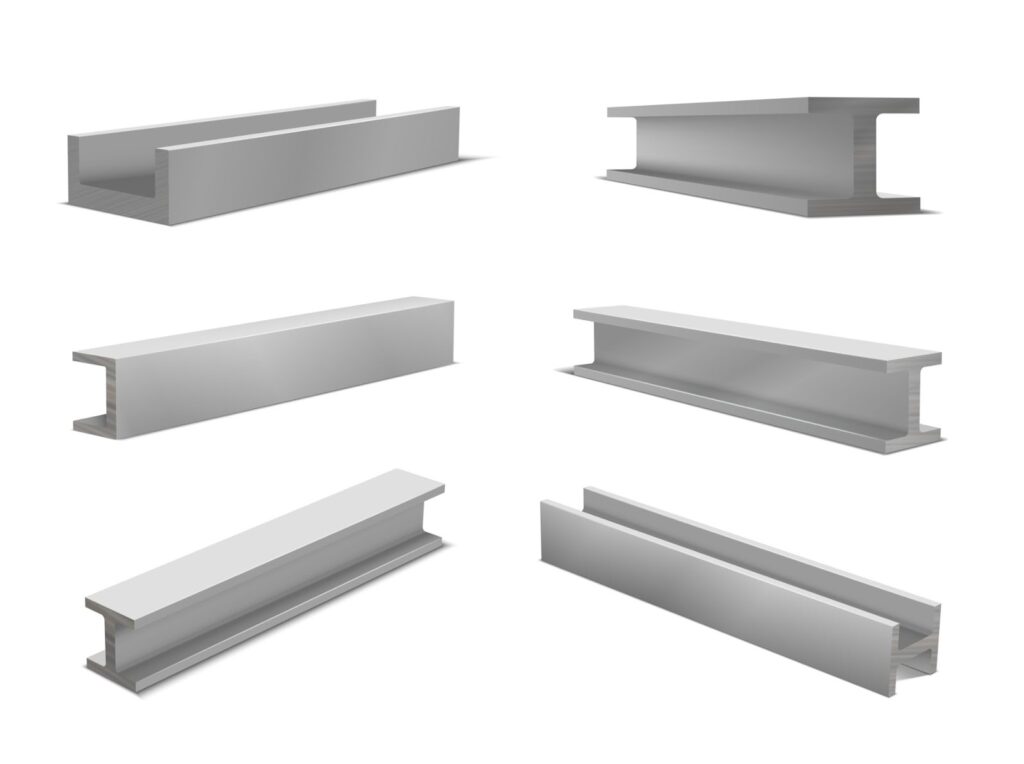

Steel beam types-

There are many ways that steel beams can be categorized. Three of the most important identifying factors are geometry, support type and cross sections.

Let’s look into each category.

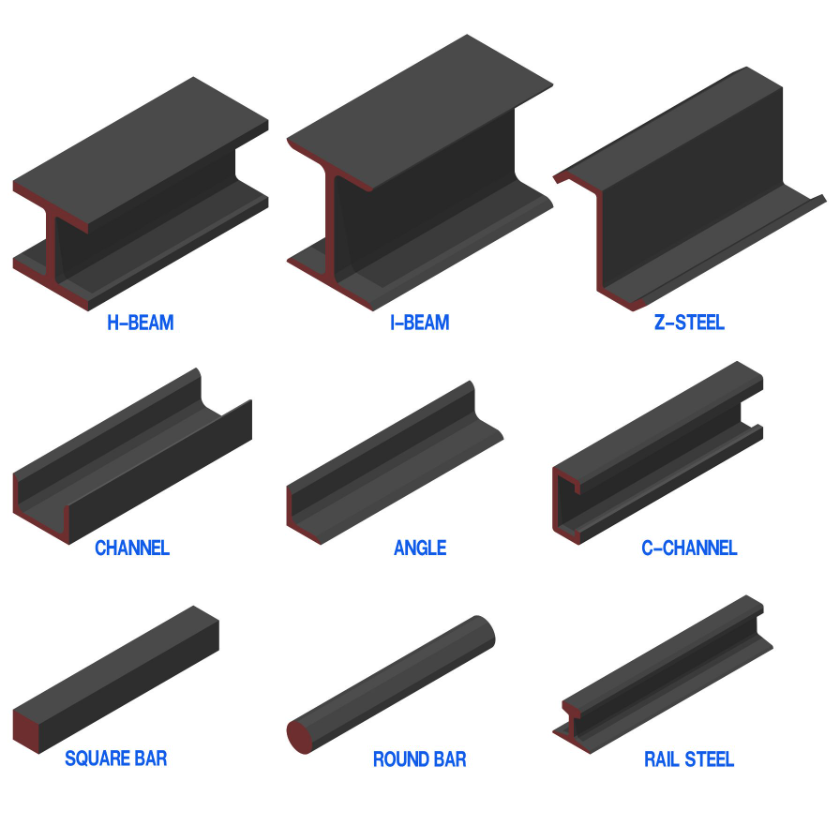

Steel beam types based upon cross sections-

I beam: I beams are considered the universal beam because almost all major structures utilize them. It is called an I beam because it is shaped like a letter I in the cross section.

W beam: W beams are commonly used in modern residential construction. Our structural engineers say they are even used more often than standard I beams. The “W” stands for wide flanges. The inner and outer flanges on a W beam are parallel. The flanges are also thicker than the web resulting in a beam that is great at resisting bend stress.

T beam: T beams have a letter T in the cross section. These steel beams are often used in framing, repairs and for roof trusses.

H beams: H beams look similar to I beams but have a slightly different cross section shape, thicker central web and wider flanges. This provides the beam with a bit more carrying capacity than an I beam. It’s common to see these beams used in building and bridge construction. H beams are also very similar to W beams. The difference is that, in H beams, the width of the flanges is approximately equal with the beam depth. In W beams, the depth is usually much greater than the width.

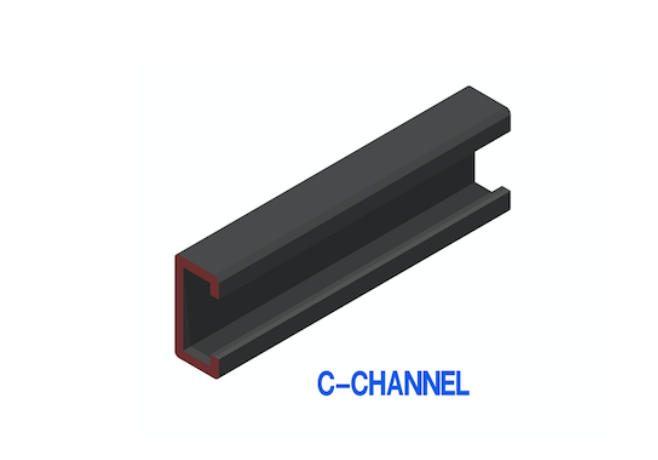

Channels: This type of beam is also known as C beams because of the C shape in the cross section. These C beams can be found in building framing, bridging and truss structures. You also may see them in conveyor rails, data transmission, tv, radio and power pylon masts.

U beam: These steel beams are U shaped. Although they do not have the enormous carrying capacity of an I beam, they are used frequently for supporting vertical loads and even horizontal loads in cross sections.

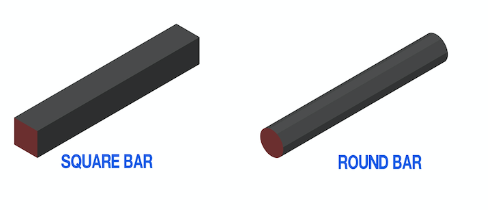

Round or square beams: These beams are solid structural steel that is either round or square shaped. It’s quite common to find these beams being used within the industrial equipment and appliance industry.

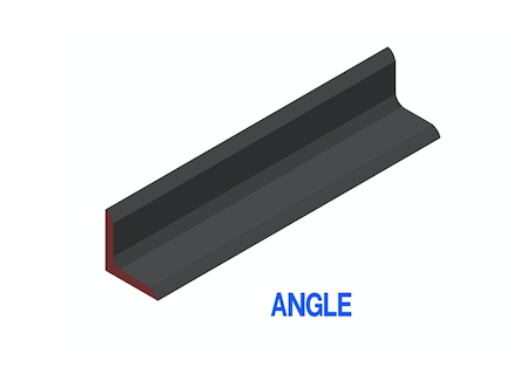

Angled beams- Angled beams are L shaped and are composed of two legs that join together at a 90 degree angle. These legs can be equal or unequal depending upon the needs of the steel beam. You may find these beams anchoring floor systems to a structure’s foundation and for angular connections.

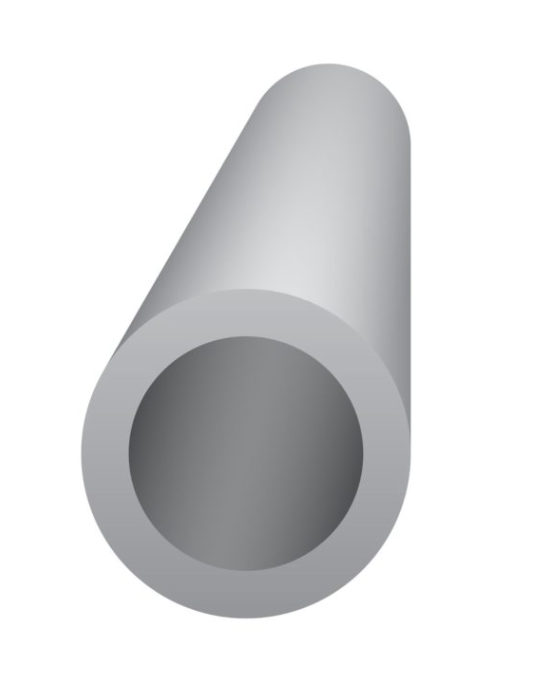

Hollow Structural Sections (HSS)- These steel beams are circular in shape with a hollow cross section. Hollow structural sections are often found in welded steel frames where members experience loading in multiple directions. They can also be used as beams depending upon the situation.

Flat bars- These flat bar “plates” are essentially a rectangular shaped flat piece of structural steel. Flat bars are commonly used as connective members in residential and commercial framing

Steel beam types based upon support type-

- Simply supported beams: A beam supported on the ends which are free to rotate and have no moment resistance. These are often found in bridges, beams in buildings, and beds of machine tools.

- Fixed beams: A beam supported on both ends that are fixed in place. These are often found in truss systems.

- Overhanging beams: This type of steel beam extends beyond its support on one side. An example is a balcony that extends out from the frame.

- Double overhanging beam- Steel beams that extend beyond the support on both ends.

- Continuous beam- Beams that have more supports than are required to provide equilibrium. One example is a uniform girder bridge.

- Cantilever- A member with one end projecting outwards (beyond the point of support).

- Trussed beam- a beam reinforced by a truss rod or formed of straight or cambered pieces joined by trussing.

Steel beam types based on geometry-

Straight beam: a steel beam that is straight.

Curved beam: a steel beam that is curved. An example is a steel framed arch.

Tapered beam: a beam that has a tapered cross section.

What steel beam size do I need?

This question gets asked a lot. The problem is…every situation is different. There is no standard beam sizing for any type of project. It all comes down to the loads the structure must carry, the span the beam must extend over and the footings and soils the loads will ultimately sit upon.

Licensed professional structural engineers size beams every day using their knowledge on building materials, industry standards and mathematical equations.

In a recent interview with one of the Complete Building Solutions’ engineers, the most frequently used beam in residential construction was discussed. Our engineers said that in modern times the AISC designates for W beams in residential construction. So, these W beams are used most frequently today. One of our engineers said that a grade 50 W beam is extremely common.

However, when asked the most common size, the engineer will always say, “it depends”. Remember, every project is different.

How to design a steel beam or calculate load capacity?

Structural engineers spend years learning how to properly design steel beams. It is not something that can be learned overnight and would definitely take more than a simple blog post to explain.

That is why structural engineers alone are required to add structural detailing (designing a beam is one example of this) to building plans in order for permits to be pulled.

Even if you hired an architect to create your building plans, an engineer will need to go through those plans and add structural detailing. It’s necessary to ensure the structural supports are adequate to keep your building standing over time.

If the project is a remodel, a structural engineer may create a structural drawing that depicts pertinent structural information that the contractor can use to perform the work and also to obtain a building permit.

If you are interested in learning about the basics of beam design, click here for a well laid out video demonstration.

Can steel beams be welded or bolted together?

Short answer…yes. Steel beams can be welded or bolted together. You may be wondering why one would do such a thing.

Well, there are situations when a structural engineer will call for this on a building plan. Specifically, this may be necessary for steel beam connections. For instance, if you need to connect two beams at a right angle, they will either need to be bolted or welded together.

Now, according to the Complete Building Solutions’ engineers, it’s more common to see steel beams bolted together in residential construction. The specific connection needed will be called out in detail by a structural engineer on the building plan.

Are steel beams expensive?

Steel beams can cost $6-$18 per foot for materials. They cost about $100-$400 per foot installed. This does not include extra labor or engineering fees for unexpected surprises or for things like: knocking down walls, reinforcing floor joists or rerouting utilities.

For comparison:

Steel beams are considerably cheaper than wood I beams (depending on if it’s hard or soft wood). They can cost anywhere from $5-$90 per foot for materials.

LVL’s usually run $3-$12 per foot for materials or $50-$100 per foot installed. They tend to be a bit cheaper than steel beams.

Concrete beams can cost $7-$16 per foot for materials. Additional sound proofing costs could incur with this option.

So, to answer your question… are steel beams expensive? Well, they are not the most expensive option nor the cheapest. They do, however, provide great head room in basements, can carry enormous loads, span long distances and hold up over time.

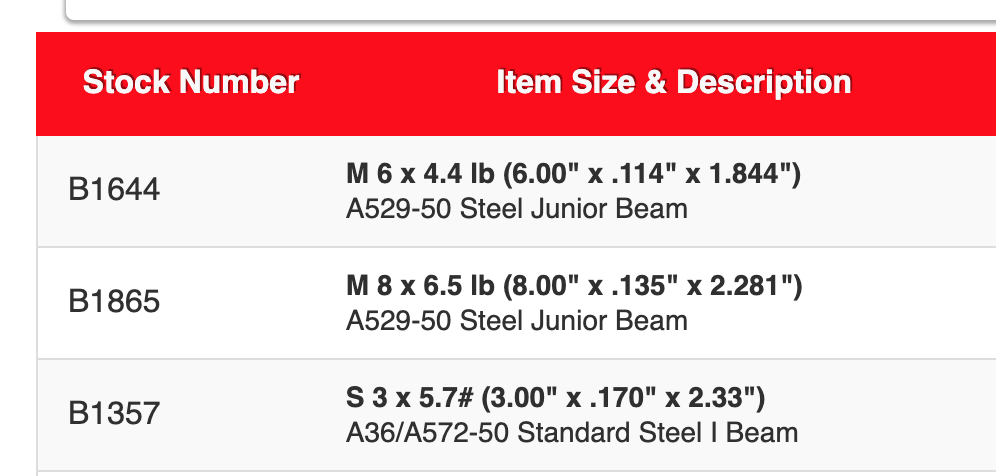

How to read steel beam sizes?

The numbers associated with steel beam sizes actually dictate how deep the beam is (how tall the “I” or cross section is) and how much it weighs per foot. The letter indicates the shape of the beam. We will provide you with some examples below.

For instance, a W 15 x 29# means that the wide flange (W) beam is 15 inches deep and weighs 29 pounds per foot.

Another example of a beam size could be S 24 x 121#. This means that the S beam is 24 inches deep and weighs 121 pounds per foot.

What grade steel beam is typically used in residential homes?

We’ve talked about this topic throughout the blog, but will touch on it again here. Grade 50 W beams seem to be the most common option in today’s residential construction.

Grade 36 was the choice for W beams prior to this. However, Grade 50 is currently designated by the AISC due to its superior strength .

There may also be instances when H or C beams may be used. Structural engineers will call out these options when necessary.

Ok. That’s all we have on steel beams for today. If you have any lingering unanswered questions, please comment below. We love Q&A and are happy to help. Otherwise, give us a call at 763-544-3355.