Floor joists are a vital structural component in the home. They are responsible for supporting the loads (people, furniture, building materials, etc) placed upon them and ensuring the floor does not collapse. All floors have floor joists; except floors built directly on a concrete slab.

You may be wondering what their specific function is and how they differ from other structural components in a building. Perhaps you’re wondering what appropriate floor joist spacing is or which kind of floor joist is best. Maybe you’re most interested in floor joist repair or if it’s safe to notch a floor joist.

All of these types of questions will be covered in this article.

If you need answers to your floor joist questions, please read on.

#1 What is a floor joist-

Floor joists are structural members that span open spaces horizontally in order to transfer loads to vertical structural members.They are necessary for dispersing live and dead loads to the floors below and eventually down to the ground. Essentially, floor joists provide the floor support needed to carry building materials, furniture, and people.

Without floor joists, your building could experience some serious structural issues including floor collapse.

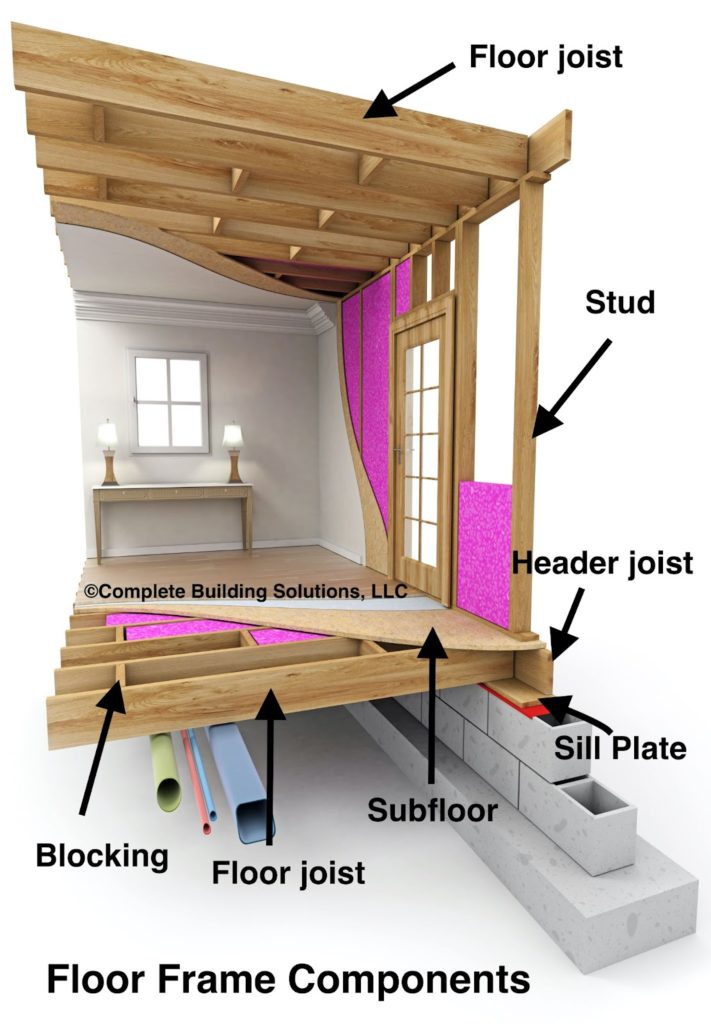

Here’s a photo.

Floor joists will usually run horizontally in between beams or other large structural supports. Their spacing and size depends upon the type of project and the span length they need to cover.

Let’s get into some of this now.

#2 What is floor joist spacing-

Most joists are placed 16 inches on center, however, they can be spaced anywhere from 12-24 inches apart.

So, how is the proper floor joist spacing determined?

Well, this is up to structural engineers.They perform calculations to determine the appropriate spacing for a building project. They will consider factors like how much live & dead load the floor needs to carry when determining the proper spacing of joists.

Most floors need to be able carry 40 pounds/square foot of live load and 15 pounds/square foot of dead load. Structural engineers will use these numbers to calculate existing loads and then perform additional calculations to size the joists (considering factors like lumber type/species/size) and appropriate joist spacing.

#3 What floor joist size do I need?-

We always recommend hiring a structural engineer to approve your building plan including joist sizing. With that being said, here are some tips for understanding floor joist sizing in your home.

Floor Joist Code Requirements-

When it comes to dimensional lumber, floor joist requirements, including joist size, will be outlined in the International Residential Code. It dictates the allowed spans for floor joists based on various joist spacing and framing materials used. It will also go into lumber types & sizing, fastening requirements and various other regulations for joist installation.

So, what factors are the codes based upon?

- Lumber size- Engineers will analyze a project to determine the appropriate size of lumber to call out. Most floor joists are made of 2×6, 2×8, 2×10 or 2×12 lumber. Larger lumber typically can span longer distances (species and grade matters too). For instance, look at the dead load 20 psf section of the IRC table below. Douglas fir larch (SS) can span 11’ 4” with 2×6 lumber, but up to 23’ 3” with 2×12 lumber. You’ll notice the floor joist spacing requirement for both options is 12” on center.

- Lumber Species- The strength of a species of wood is considered when selecting lumber for framing. Common lumber types are: southern yellow pine (common in the southeast part of the United States) as well as SPF: spruce, pine and fir. Southern yellow pine has a high durability and strength. SPF is very light weight but is comparable or stronger than many hardwoods.

- Lumber grade- Commercial lumber is labeled with a “grade”. This grade communicates the quality of the wood to the buyer. Select grade is the highest quality/strongest lumber that can be purchased; there are no imperfections such as blemishes or knots that could weaken the material. Other options for grade could be 1, 2 or 3. Grade #2 is most common for homes because it’s strong enough to get the job done but also affordable. Joist span tables, such as the one above from the IRC, provide max span lengths for all grades of lumber mentioned.

- Structural Loads- We’ve talked a bit about the structural load requirements on joists already. Projects may vary in load requirements based upon location, size, or other factors. You will see this in the floor joist span requirements in the IRC codes as well. There is one chart for a 30 psf live load and one for a 40 psf live load. Engineers are trained to understand load requirements for various projects.

As you can see, sizing floor joists depends upon many factors. There is no one-size-fits-all.

Note- Even though the IRC chart denotes 2×6 lumber, it really isn’t used often in modern framing. It can, however, be found in older homes.

Another note- For engineered wood, see manufacturer span tables or speak with a structural engineer.

If you have concerns that your floor joists are undersized, first pull out the IRC chart and look. It is also a good idea to have a structural engineer inspect the joists.

Get a free quote on your project!

Ready to start your project? Reach out to Complete Building solutions and get a quote absolutely free.

#4 What is a floor joist span?-

Floor joist span is the length and individual floor joist extends between load bearing walls or beams.

Take a look at the IRC floor joist chart below.

The red box indicates the maximum floor joist spans for various lumber species & size. For instance, Douglas fir-larch SS with a joist size of 2×8 can span 15’ when joist spacing is 12” on center.

In latent terms, this means that your joists are made of Douglas fir-larch with an SS grade (very strong grade), built out of a 2×8’s and will be spaced 12” apart under your floor. A single joist with the above criteria is able to cover (span) 15 feet.

Structural engineers use charts like these to dictate the appropriate joist span on building plans.

#5 Can floor joists be 24” or 16” on center?-

It’s amazing how often we get asked this question.

Floor joists can be spaced anywhere from 12-24” apart. It’s most common to see them spaced 16” apart.

Engineers will look at components such as lumber size, type, grade, and load requirements when determining the correct floor joist spacing.

The IRC’s floor joist span chart depicts the correct floor joist spacing based on the factors above. To access the chart, click here.

Please remember to hire a structural engineer anytime you are making structural changes to a property. They do not look at one isolated section of a building; instead they analyze the structure as a whole and examine how loads are transferred throughout the building.

#6 What size floor joist is needed for a deck?-

Floor joist size has a lot to do with the span you are wanting to cover. But, in order to know the exact criteria for your deck, be sure to check your a) state and b) city building regulations.

For instance, if you wanted to build a deck in Minnesota you could check the most recent building code for MN. In this case, it’s the 2020 Minnesota Residential Code.

Note- In Minnesota you will need a building permit for a deck when:

• When a deck or a platform is more than 30 inches above adjacent grade.

• When a deck or platform is attached to a structure with frost footings.

• When a deck or platform is part of an accessible route.

The Minnesota Residential Code provides a 3 page PDF dictating the criteria for decks including floor joist requirements.

Here’s what it says about joists for decks.

Once you’ve looked into your state’s joist spacing criteria, be sure to look into your city’s requirements as well. For instance, the city of Bloomington, Minnesota provides a 4 page detailed description of requirements. The sheet is titled Residential Decks Information Sheet.

Here is a chart from that document depicting joist spacing and sizing requirements for Bloomington, Minnesota.

As you can see, the chart is based off of Southern Pine Lumber with a grade of #2 or better.

So, back to the question on what size floor joist to use for a deck, again, there is no one size fits all answer. Your state and local codes will provide you with the requirements.

It’s important to consider the span you are wanting to cover. As seen in the above chart, in Bloomington, Minnesota, you can use 2×6, 2×8, 2×10 or 2x12s for joists. The longer the distance a joist needs to span, the larger the joist needs to be.

Bonus- If you were wondering about joist spacing (as opposed to joist sizing) for decks, this can be found on the above chart as well. For instance, you can see that deck joists can be spaced at 24” on center, 16” on center or 12” on center. The span needing to be covered will often dictate joist spacing.

Remember, it’s always a good idea (and often a requirement to pull a building permit) to hire a structural engineer to size joists for your deck. Their stamp of approval on the deck design guarantees a structurally sound plan.

In some cases, the city may require a structural drawing. Read about this here.

#7 Can you cut or notch floor joists for plumbing or wiring?-

It’s important to preface here that you should never cut into a structural member without speaking with a structural engineer first. A single cut could be devastating to your home’s structural integrity.

We’ve actually had clients call us in panic due to an over-notched joist.

Yikes.

These mistakes can become expensive to fix depending on a) whether structural damage was done and b) the amount of labor and materials needed to remedy the situation.

But, back to the question, yes floor joists can be cut for both plumbing and wiring provided you follow the rules.

These rules are laid out here by the IBC & IRC. Again, do not attempt this without professional guidance.

Here is a photo of a floor joist that was notched incorrectly leading to joist failure. It needs to be repaired ASAP in order for the home’s structural integrity to remain intact.

#8 What are the best floor joists-

If by “the best” you mean the strongest, well then we are talking about lumber grade. As we discussed earlier in this post, lumber is given a grade to denote its strength. Knots and defects will weaken the structural integrity of lumber. So, lumber with a higher grade is ultimately stronger.

Now, the most common lumber grade used for building projects is #2. It’s strength and quality is sufficient enough for framing projects and it is also easier on the budget than structural select or #1.

If by “the best” you mean which type of floor joist is best, then the answer is….it depends. The 3 most common types of floor joist systems are: dimensional lumber, floor truss systems, and TJI’s. Each floor joist system has its pros and cons.

Read #9 below to learn more.

#9 Common types of floor joists-

Did you know that not all joists are made with dimensional lumber? We’ll discuss the 3 most common floor joists here.

Common floor joist systems:

- Dimensional lumber (usually 2×8 or 2×10)–

Dimensional lumber (solid lumber) is still quite common today. Traditionally it was the floor joist type that was used up until the early 1990’s (engineered wood started to become popular). Dimensional lumber is available widely at lumber yards and can be sized using standardized building codes. It’s cheaper up front but ultimately doesn’t span the distances engineered wood floor trusses can.

- Floor trusses (depth 12-24”) –

Floor trusses are engineered wood products constructed with 2×4’s on both top & bottom and a “web” in between fastened with metal plates. They span much greater distances than dimensional lumber, use less lumber than other floor joist systems and provide an open design allowing for easy installment of HVAC ductwork, plumbing lines, and electrical wiring. Contractors love this. Keep in mind that they can’t be modified on site.

- TJI – Truss Joist I-Joist System– TJI’s are essentially Wood I-joists that look similar to steel I-beams. See the photo below.

Notice there is a top & bottom flange with OSB (could be plywood too) fastened in between. This type of floor joist system is chosen when there are large distances to span in a building. Think, open floor plan. Other perks are that the structural load carrying capacity is much higher than other floor systems and there is much less chance of bowing or shrinking with these materials. Some contractors prefer TJI systems to floor truss systems simply because they flex less.

Remember, regardless of what floor joist system you use, floor load must be supported. Each system will be designed to ensure it can hold the loads placed upon it. Typically these systems will be designed by an engineer to hold a live load of 40 lbs/square foot and a dead load of 15 lbs/square foot.

#10 How to tell where floor joists are-

If you are trying to locate your floor joists, the easiest way to do so is by using a stud finder designed for floors.. Simply turn it on, place it on the floor and move it back and forth until it lights up. Remember, most joists are spaced 16” on center. You can use this knowledge to predict where the studs may be.

No stud finder? No problem.

Here is another method:

- Wrap a hammer head with a small towel.

- Lightly tap the hammer on the floor, moving left and right, until you hear a change in sound from hollow to solid. Boom, you’ve found your joist.

- Feel free to mark this joist with tape.

- Measure from the center of the masking tape out 16 inches (either left or right).

- Tap the new location with the hammer. If you are getting solid sounds, mark the spot with tape.

- Continue this process until all joists have been uncovered.

#11 Are joist hangers required by code?-

99% of the time joist hangers will be required by code. You can read about joist hanger requirements in the IRC, state and city codes.

Below is a snip of code from the International Residential Code regarding framing anchors for joists framing into wood girders.

Below is a snip of code from the Minnesota Residential Code regarding framing anchors for joists framing into wood girders.

* A wood girder is the technical term for the main beam of your home. Since the main beam is supported by vertical posts, it’s considered a girder.

In regards to city requirements, here is another diagram from the city of Bloomington (MN) targeted towards deck construction. There is a note regarding joist hangers. Essentially, they request that you use the “proper size” joist hanger for the joist size used.

*Bloomington, Minnesota Residential Decks Information Sheet

You may be wondering what this means?

A general rule of thumb is that joist hangers are the same size as the joist size.

In SOME cases, you could use a hanger that is one dimensional size less than the joist depth. For example, a 2×6 hanger may be allowed for a 2×8 joist.

Your structural engineer and contractor will be able to help you navigate joist hanger requirements. These sizings will be denoted on your building plan and will be reviewed by the city in order for a permit to be pulled.

#12 Where to buy floor joists?-

Floor joists can be purchased through most lumber yards, private companies and home improvement stores like Home Depot.

Most contractors have their preferred vendors. However, if you are in the market, simply do some research. Search around on a few websites to see what’s out there.

#13 Can you use Lvl for floor joists –

LVL floor joists can be used in cases where large loads are present. They are stronger than most other floor joist systems, but are very expensive. In cases where a very stiff floor is required or a long span needs to be achieved, they could be used. Again, it’s not often a preferred choice due to cost.

Note- LVL stands for laminated veneer lumber and looks a bit like plywood. The main difference between plywood and LVL is the grain of the engineered wood; plywood changes grain direction with each layer while LVL keeps the grain direction the same.

#14 Who repairs floor joists?-

A simple online search will pull up several companies that can repair joists.

One question to address here is why your joists need to be repaired. Were they undersized? Has water damaged them? Was a joist mistakenly over-notched or cut?

How do you know your joists are damaged?

If there is any concern here, it may be a good idea to have a structural engineer come take a look.

Read here to learn what a structural engineer inspection entails.

Whatever the reason is, fixing a damaged joist is essential. They are majorly important to the structural integrity of your home.

A structural engineer can tell you if your joists are up to code or if they have failed. They can also write you a scope of repair. It’s possible that they could call out sistering the joists or if a more serious solution, such as using jacks to lift the building off the joists, is required.

Signs that your floor joists could be damaged:

- Sagging floors

- Sagging or sinking beams

- Bouncy floors

- Rotting wood

- Jamming crawl space door

- Bowing crawl space supports

- Cracks on the crawl space walls

If you have suspicions that something is wrong with your floor joists, reach out to a professional right away.

#15 Can I remove floor joist cross bracing?-

Technically, yes, you can remove floor joist cross bracing. However, structural engineers do not recommend it in most cases.

Floor joist cross bracing is there to prevent the joist from moving laterally. If they are removed, the chance of lateral movement occuring is much greater. For obvious reasons this is not great.

You may be wondering why one would want to remove floor joist cross bracing in the first place.

Usually, it’s because a homeowner wants to make room for plumbing or HVAC.

An engineer may tell you it’s ok to remove cross bracing if an HVAC duct is being installed. The HVAC duct may act similarly to cross bracing, preventing lateral movement in the joist.

If you have other motivations for wanting to remove cross bracing from floor joists, contact an engineer for advice.

#16 What is floor joist bridging?-

Bridging is a joist bracing method used to support floor joists and prevent deflection. The cross bracing discussed above is a type of bridging which entails “x” pattern strips in between joists.

There are several types of floor joist bridging:

- Solid wood joist bridging

- Steel joist bridging

- Wood composite

Building code requires bridging when floor joists are greater than 12 inches wide.

Remember, engineered wood must be installed via manufacturer’s instructions regardless of bridging code. Failing to follow manufacturer’s specs can void a warranty and cost you a large sum of money to repair mistakes.

Well, there you have it. That post included our top 16 most frequently asked questions regarding floor joists. If you are interested in learning about another type of joist, ceiling joists, click here.

If you have any additional questions, please feel free to follow up with us at 763-544-3355.