What is a helical pier-

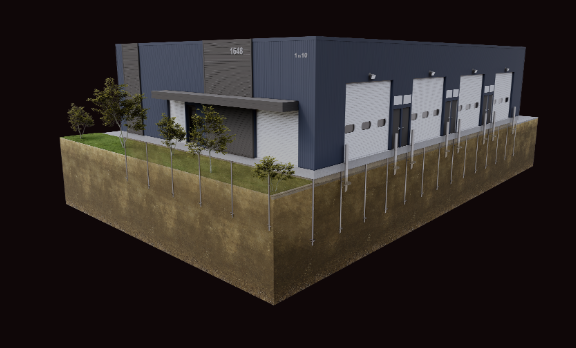

Helical piers are essentially steel pipes resembling corkscrews that are used to secure new foundations or repair existing foundations. They are used when standard foundation designs cannot provide adequate support due to existing soil conditions.

Many structural engineers will suggest a deep foundation design such as this when build soils are improper especially if the foundation will carry heavy loads. The shape of the piers enable them to be easily screwed into the ground to a desired depth determined by a structural engineer. The main goal is to drill deep enough to reach stable undisturbed soil to lock the pier into place. Typically, the larger the helical pier and the deeper it’s installed, the larger the structure it must carry.

These helical piers are installed once the foundation has been dug, but before concrete is poured. The ease of installation and the structural support provided makes helical piers a popular choice for many projects.

What are helical piers used for-

Helical piers are an amazing deep foundation design solution utilized when soils are poor or when a licensed engineer calls for it . It may surprise you how versatile these helical piers are. So versatile that they are used in all kinds of construction projects ranging from civil engineering to commercial buildings and even residential jobs.

Helical piers can be used for:

- Condos

- Parking garages

- Solar and wind farms

- Residential construction: new construction, remodels & foundation repair

- Chemical, gas & liquid pipelines

- Marine construction

- Shoring and support of excavation

- Railroad projects

- Industrial applications

- Amusement parks

- Deck installation

- Docks

- Harbors

- Wetlands

It’s important to remember that every building scenario is unique. For example, just because you know your property has unsuitable soils, does not mean a helical pier system is the right solution for your project (although it could be). If you want to install a deck off your building, an engineer may decide a diamond pier foundation system is the best option because it’s easier to install and provides adequate strength for the soils present. Or, perhaps a soil correction is a better route. Always get an engineer’s opinion.

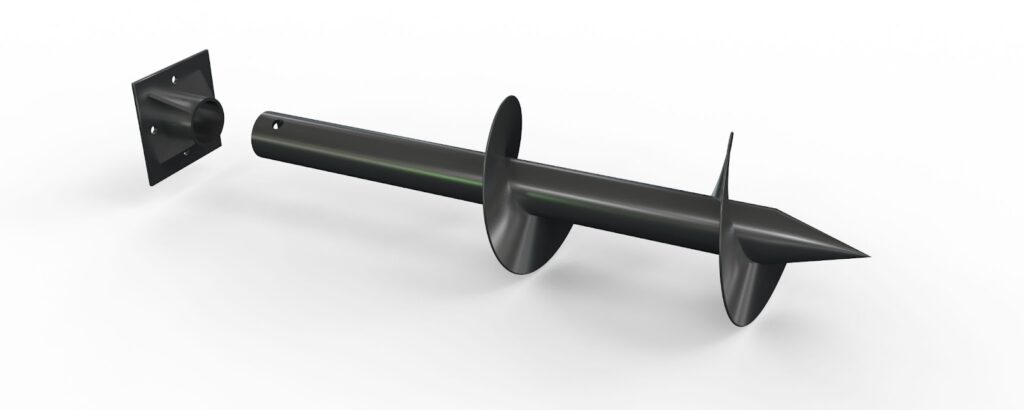

What do helical piers look like-

Helical piers honestly look similar to an auger (see the photo above). The corkscrew appearance is the distinguishing characteristic of a helical pier. They are designed to be structurally supportive but also easy to install. The shape of the pier eliminates needs for heavy excavation. This is because hydraulic hand tools or mini excavators are typically used to screw the pier into the ground (larger projects may call for larger equipment). When conditions are appropriate, helical piers are easier and more affordable to install than a deep pile foundation system in which large equipment is essential to pound the piers deep into the ground.

How deep do helical piers go-

A licensed engineer will design your helical pier foundation system. How deep the helical piers are driven into the ground is only one component of the design. Engineers will dictate the actual size of the piers and how far apart they must be spaced as well as the depth they will be driven. All of these features are essential for transferring and supporting the loads above.

In general, when all factors have been thoroughly considered by a professional engineer, it is common to see helical piers being drilled into the ground at depths of 10-30 feet deep. The goal is to drill the helical piers through the compressible (unstable) soils to reach load bearing soils. Helical pier foundations spread building loads over a large area of land because there are more than just a few contact points. Engineers space them appropriately in order to disperse heavy loads evenly across an area. The piers move deep into the earth to transfer the foundation loads to the more stable soils.

Types of helical piers-

There are two different types of helical piers: round shaft piers and square shaft piers.

Round Shaft Pier-

Round shafts are commonly sized at 2 ⅞” diameter, 3.5” diameter and 4.5” diameter. They are frequently used for compression applications and have greater load capacity and lateral strength.

Square Shaft Piers-

Square shaft piers may be found in 1.5”, 1.75” and 2.25” round corner square. These kinds of piers are well suited for projects requiring tensile strength and torque capacity.

Do helical piers work in rocky soil-

Unfortunately, when attempting to use standard helical piers in rocky soil, problems can arise. Unexpected obstructions can absolutely stop a project in its tracks. You see, structural engineers will call for helical piers to be installed every so many feet ie) every 10 feet under the foundation. If a large boulder in the earth prevents a helical pier from being installed, then that foundation is not following the engineer’s specifications and will not transfer loads properly. This is a huge problem.

It’s for this reason most contractors/engineers will not attempt to utilize standard helical piers in rocky soil. There are some products on the market that are capable of drilling through obstructions. One such product we’ve seen is the ROCK-IT 3 helix (6-8-10) square shaft pile. For various reasons, square shafts handle rocky soil better and the carbide tip reduces spiking of torque and chatter during the installation process. These features allow the piers to penetrate frozen, rough and rocky terrain where traditional helical piers can’t.

Get a free quote on your project!

Ready to start your project? Reach out to Complete Building solutions and get a quote absolutely free.

How long do helical piers last-

Most professionals will say that a helical pier can last up to 150 years. And this is absolutely true when soil conditions are favorable. In fact, in a scenario such as that, it’s estimated that a helical pier could even last up to 350 years.

In reality, how long a helical pile lasts has nothing to do with the product itself (as long as it was designed properly and well built). Soil conditions are the number one factor determining how long a helical pier will thrive. Movement, both lateral and vertical, can cause premature wear on the piers.

The following regions demonstrate significant ground movement which can lead to faster wear:

- Coastal areas

- Mountainous areas

- Areas with fault lines

The following soil conditions may also cause faster wear on helical piers:

- Acidic soils

- Rocky terrain

- Quickly eroding soils

A licensed engineer or helical pier professional who knows your specific building site will be able to give you an estimation on how long your helical piers will last.

Do helical piers rust-

Steel has the capacity to rust when the conditions are right. In regards to corrosion, Structural steel in soil is typically categorized as a) corrosion in disturbed soil and b) corrosion in undisturbed soil.

Let’s define corrosion.

Corrosion-a process in which a solid, esp a metal, is eaten away and changed by a chemical action, as in the oxidation of iron in the presence of water by an electrolytic process. slow deterioration by being eaten or worn away.

- Disturbed soil- Disturbed soil has had more oxygen introduced to it because of digging and backfilling. In general, more oxygen exposure means more corrosion. The corrosion rate in disturbed soil is also affected by the following factors:

- Soil sensitivity

- pH

- Chloride content

- Sulfate content

- Sulfide ion content

- Soil moisture

- Oxygen content

When measurements of these parameters are taken, it’s been thought that a generalized idea of soil corrosivity is possible. However, it’s challenging to understand the mechanisms occurring between the various players involved. Because of this, there are no truly accurate ways to predict corrosion rates. We must rely on comparisons of site conditions, existing soil corrosion parameters, and historic information from similar sites. Ultimately, it is possible for helical piers to corrode in disturbed soils but it’s challenging to predict.

- Undisturbed soil- Undisturbed soil contains significantly less oxygen than disturbed soil. Because of this, steel piers do not seem to be affected greatly by corrosion regardless of soil types and properties. One thing to note- helical piers are mostly in contact with undisturbed soil. However, the uppermost part of the pier, near the top of the anchor shafts, are exposed to disturbed soil and therefore higher oxygen contents. This is when coatings like hot-dipped galvanization and epoxy become useful for preventing corrosion. Another technique could be corrosion allowance where engineers will call for an increased thickness of metal in order to compensate for predicted metal loss.

Helical pier corrosion protection-

In order to prevent corrosion, some helical piers will have a galvanized coating on them. Essentially this is when bare steel is dipped into molten zinc. This coating will actually protect the metal mechanically and is extremely powerful.

It works in 2 ways.

- By preventing corrosive substances and environments from touching the underlying steel.

- Galvanic corrosion- This occurs when 2 metals with different chemical make ups are in contact with each other when an electrolyte (think salt) is present. One metal will act as an anode and one will act as a cathode (it depends upon the atomic structure which is which). The anode will degrade faster than the cathode. Zinc will typically act as the anode, therefore the corrosion rate of the steel (cathode) will be slower.

Another note- Because of its durability, it’s hard to damage the coating which is often a concern with any kind of building material on a job site. Most applications only call for the upper part of the anchor to be coated since this is where the disturbed soil is and where most oxidation will take place.

Are helical piers expensive-

There are an infinite amount of factors to consider when discussing the costs of helical pier foundations. If helical piers are necessary, it’s because your building site has unique conditions requiring a more specialized foundation system. A structural engineer will need to be at the helm ensuring that the foundation design is adequate for the loads it must carry.

Here are some components that must be considered:

- Type of project

- Helical diameter

- The engineer’s specifications

- Number of helices on the pier

- Soil type and conditions

- Building load requirements

Only once these factors have been reviewed by an engineer can an accurate price be discussed. In general, a standard 2-⅞” helical pile averages around $30/square foot. Most piers end up being about 20 feet long. This can push the costs to about $600 for one helical pier. When installation costs are factored in, you’re looking at $2,000-$3,000 per helical pier. On average, a residential home will need 5-10 helical piers. Based on these numbers for a residential project your final cost could be $15,000-$30,000.

Are helical piers better than drilled concrete piers (caissons)-

First off, let’s discuss what a drilled concrete pier aka caisson is.

Caisson foundations are utilized in deep water or soft soils. Large, wateright cylinders are sunk into the ground and poured with concrete. This base allows for structures to be built on top of it. Bridges, docks and large structures will typically make use of caisson or drilled concrete foundations.

Let’s do a little comparison between helical piers and drilled concrete piers aka caissons so you can decide for yourself what is better.

Price-

When it comes to raw materials helical piers are more expensive. However, labor costs and installation time are significantly less than concrete. Also, helical piers have a greater bearing capacity than concrete piers meaning that less materials can often be used. Economically, helical piers can often make more sense especially because they can last over a hundred years and are less susceptible to cracking and shifting than concrete.

Speed-

Without a doubt, helical piers are quicker to install. In average soils it takes about 10 minutes to drive a helical pier into position. They require less labor, no digging and no curing time. Overall expenses are greatly decreased because of this.

Building sites disturbances-

The process of installing helical piles is quick and easy. It also produces minimal to no noise, dust or vibrations. Avoiding the use of heavy equipment preserves your lawn, keeps your neighbors happy and again saves on labor and equipment costs. Concrete, on the other hand, does create a bit more of a mess and requires the use of heavy equipment.

Excavation-

There is no excavation required when installing helical piers. With a drilled concrete pier, holes must be drilled, equipment is needed and it is time consuming.

Loading–

With helical piers it’s possible to add loads immediately after installation. Drilled concrete piers must wait for the concrete to cure before loading is structurally safe.

Helical piers are less susceptible to frost heave because of the shaft design. Drilled concrete piers often rely on skin friction for bearing. They are installed only to frost depth and have a large surface area which makes it susceptible to heaving.

Appropriate for many soil types-

Helical piers are meant for unique soil conditions and building sites. They can be used to provide a strong foundation for structures in weak or unsuitable soils.

So, back to the question on whether helical piers or drilled concrete piers are better…what do you think?

Can helical piers be adjusted-

There may be times, especially when building on uneven terrain, that your structural engineer may call for adjustable heads on your helical piers. Typically these will be seen with decks or projects with lighter loads. They are quite useful for leveling deck posts to the desired height. Fine tuning the elevation in this way saves a ton of time and headaches.

Who installs helical piers-

It’s best to hire a certified helical pier installer. This means that a contractor took the time to go through a helical pier manufacturer’s training in order to be proficient at the task.

Many times throughout this article we’ve said how easy it is to install helical piers; it is easy for those trained in it.

There are several factors that can make or break your helical pier installation.

- Load charts- Overtime, engineers have generated load charts that depict the relationship between torque and capacity. You see, the installers must apply a specific amount of torque to the pier depending upon the loads the foundation must support. Helical pier installers must be able to read and understand the load charts.

- Calibrate- The equipment utilized on site must be calibrated properly. For instance, if a mini excavator is used to drive the pier, then it should have a calibrated hydraulic anchor drive head.

- Proper training- Ask your contractor which helical pier manufacturer they work with and check out their website. Does the company offer good training and has your contractor been certified with them?

Helical Pier vs. Diamond Pier-

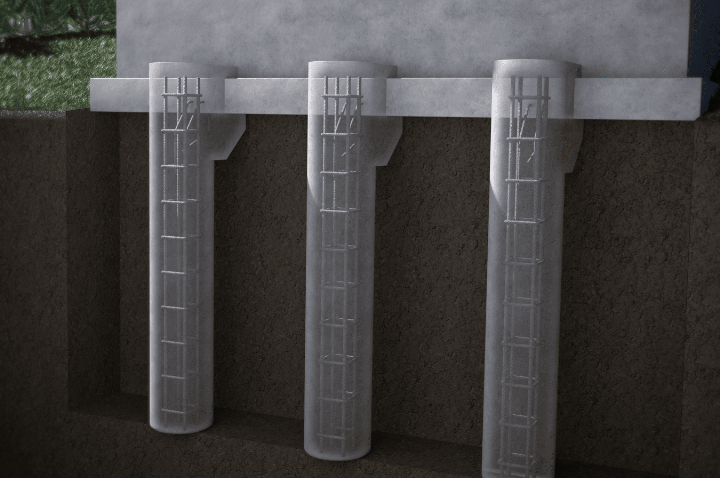

Diamond piers are another specialized foundation system utilized by structural and geotechnical engineers for specific situations and soil conditions. They are precast concrete piers with a diamond-shaped footing.

One thing that makes them a sought after solution is the ease of installation; no excavation or concrete curing necessary. Essentially the concrete head is placed into position and a hydraulic drill is used to drive four bearing pins into the earth. It’s a much easier installation than even helical piers. If you’re interested in learning more about the installation process click here.

Other key points to mention in regards to diamond piers is that they are frost heave resistant, and can be utilized in areas with high water tables and expansive soils. This is why they are so often utilized in areas with clay soil such as Plymouth, Minnesota. Our engineers frequently call for diamond piers in this part of the surrounding metro. They are easy to install, have great bearing support and function well in poor soils.

On the flip side, the concrete nature of the product can create a need for specialized installation equipment. If this is the case, costs will increase due to equipment rentals. It’s also important to factor in how much physical space is available on the job site. Certain equipment may not fit or be suitable for the project.

Another downfall to diamond piers is that they are limited on how far they can be driven into the ground. Very weak soils or unstable soil conditions may prevent a homeowner from utilizing these piers. Be sure to consult with a structural or geotechnical engineer to determine the best foundation system for your home.

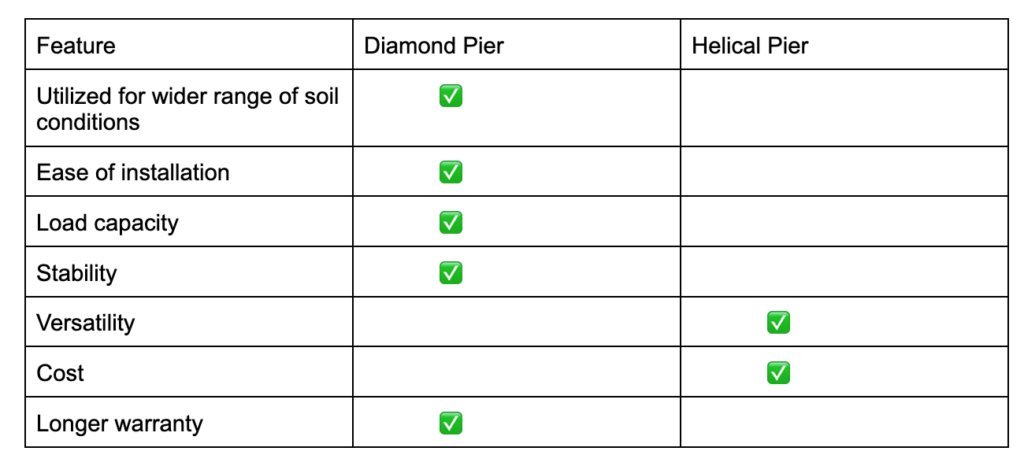

So, what’s better? Well, each foundation system is unique and used for different scenarios. We can’t say one is absolutely better than the other. Here is a summary of some of the key characteristics.

Helical Piers vs. Push Piers-

Push piers can be used as a foundation repair application when settlement is an issue. They are essentially steel piers that are placed around an existing foundation and hydraulically pounded into the soil to provide strength to the existing footings/foundation. The goal is to drive the piers through weak soils under the foundation in order to reach more solid soils that can provide strength and stability to the home. This type of system can actually be used to hydraulically lift a fallen foundation.

They are also great for heavy loads such as in large industrial construction projects. They rely on the building’s weight to essentially hold them in place. It’s not as common to find these foundation systems used on new construction residential builds because these projects tend to be more lightweight.

Push piers are different from helical piers in many ways.

- Pushed not screwed into the soil- Think of push piers as resembling a nail and helical piers resembling a screw. Nails are pushed or pounded while screws are drilled (requiring torque) into the earth to provide stability to a foundation.

- Better for heavy loads- Push piers are often used to handle heavy loads. This is because the weight of a structure physically pushes the pier downward until it reaches stable soils. They will go as deep as the weight of the house will push them. Helical piers tend to be more useful with lighter loads although they may be a good fit for heavy loads in certain applications.

- Safety- Helical piers have a higher safety factor than push piers do. Essentially, it takes more weight to “max out” a helical pier than it does a push pier. This has to do with the fact that helical piers are installed separately from the foundation. A torque motor drives these piers without relying on your home’s weight. Because of this, the piers can be installed very tightly to hold more weight all while providing structural integrity to the home.

We hope you found this article on helical piers informative. If you have additional questions please reach out at 715-544-3355. Thank you.